When I purchased my first serger, it arrived during the Great Midwestern Blizzard of 2010. I waded through kneedeep snow to fetch the battered box from my apartment’s rental office, opened it, set it up, stepped on the pedal…and…

…nothing! The machine’s motor went WRRRRRRRRRRRRRRRRRRRR but nothing moved. I carefully checked the manual to make sure I hadn’t missed a hidden activation switch of some kind, but it didn’t look like I’d missed a setup step. Perhaps it had been damaged in transit?

If so, the fact that the motor seemed to be working seemed promising. So I decided this was a great excuse to take it apart to see if I could fix it.

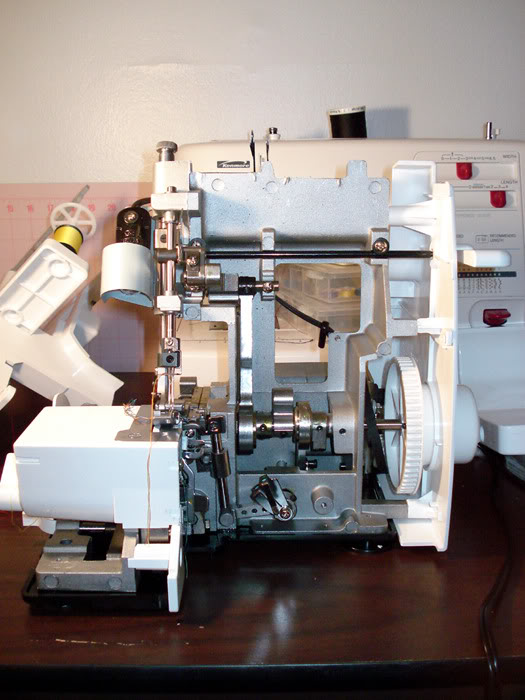

The sadly nonfunctional serger.

I unscrewed the back and the back side to see if I could peer in and figure out what was wrong.

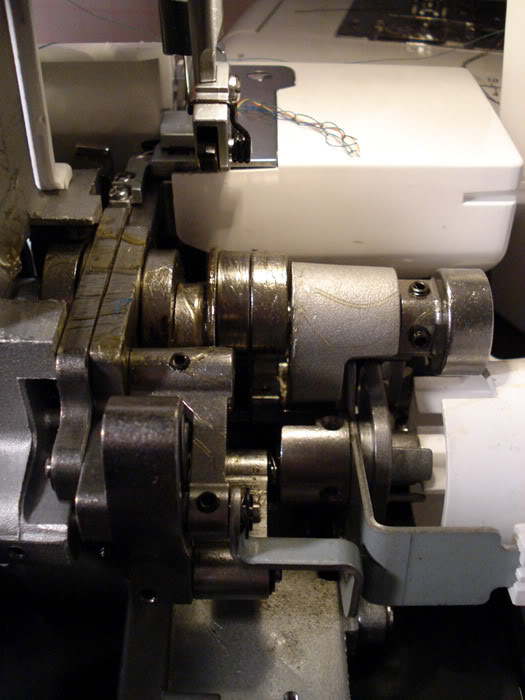

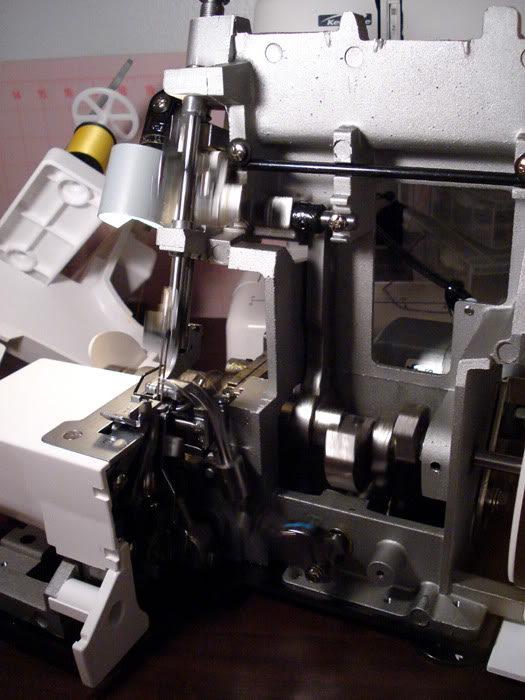

I hadn’t realized there was a giant chunk of machinery behind the presser foot. Pretty interesting.

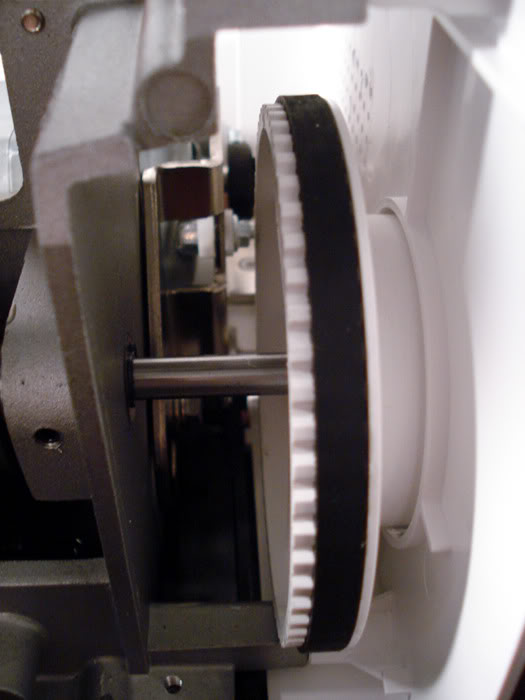

Ohhhh, this could be causing my problem! It was kind of difficult to get at the back half of the loop (I had basically no tools in those times) and I wanted to inspect it more closely in case it turned out something else was wrong. So, I continued with removing the panels to see if I could access it from the front.

The screw on the right in the first image held the front plastic plate to the machine. However, the flip down plate was blocking my path.

So, I flipped the serger over and removed these two screws.

BAMMO! Path unblocked.

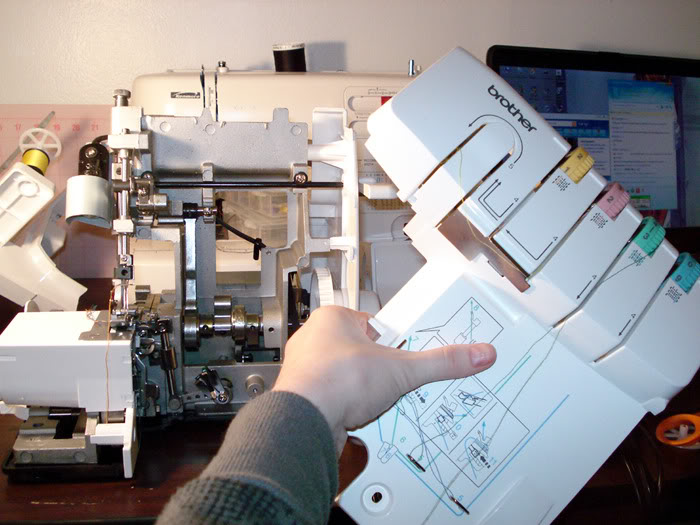

An action shot!…a blurry one, because back in 2010, I didn’t have a smart phone. Then I was able to carefully wriggle the front plate free.

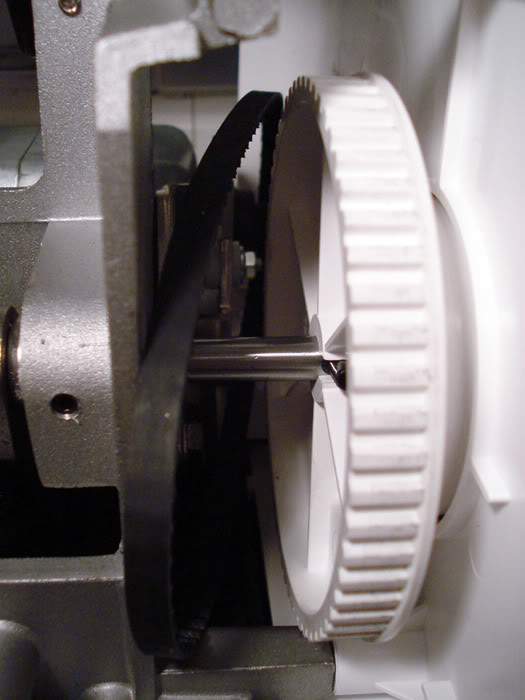

Here are the cute intestines of my serger! (Note the flailing belt on the right.) I could also see the little mechanism that directs the lifting/lowering of the presser foot.

When I was done ogling the mechanical engineering, I pulled the belt forward and popped it on. Then, it was time for the moment of truth: pressing the foot pedal.

Vroom! :D

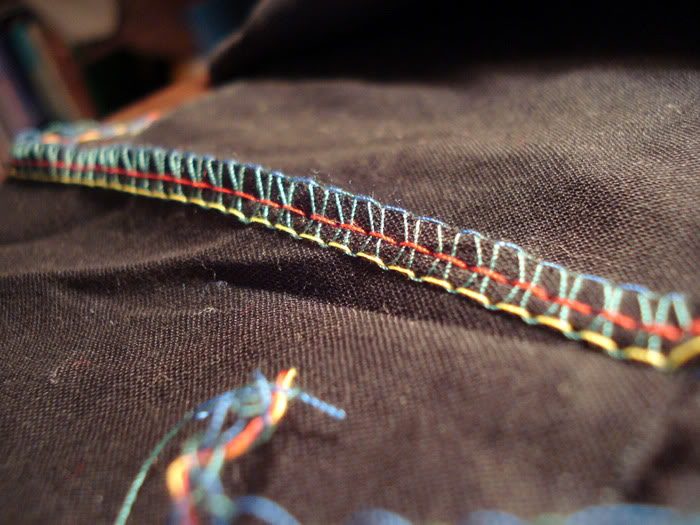

Rainbow colored test stitching. :)

Then I put it all back together again. Not a hard “repair,” and saved me the gas money of driving back out to the post office.

Closing Thoughts on the Brother 1034D

When I first became able to afford a serger, my options were limited to the absolute bottom of the market (~$200 budget). This restricted an ocean of potential choices down to a tiny handful; out of these, reviews indicated that the Brother 1034D was by far the best choice. This was suprising to me since at the time I was generally pretty skeptical of low end Brother sewing machines based on my limited interactions with them.

Sergers in particular have a reputation for being relatively difficult to use regardless of make or model. Many people struggle to troubleshoot tension issues on a normal sewing machine, and that takes only two thread inputs, compared to a serger’s four or more. The inherent complexity of spamming 4+ threads at precisely timed intervals can of course only be exacerbated by known troublemakers with questionable engineering.

It is extremely common to find sergers with extremely poor online reviews in aggregate, with the challenge typically lying in distinguishing whether the user is retarded or the machine is just a total piece of crap. This is most challenging for the lowest end models where novices and retards have the most overlap. Interestingly, the Brother 1034D had atypically good reviews (4.6/5.0 across 2,000+ reviews, in a time before review-gaming really got under way), and many of those were written by people new to using any sort of serger at all.

Despite my initial trouble with the belt, the serger has served me faithfully now for many years. It’s a great machine and I still highly recommend it. I bought it in 2010 for $200, although as of 2024 it now goes for $280 on Amazon. For basic serging needs I think you’d still be hard pressed to find better. It might lack a lot of the bells and whistles found in the $1,000+ category, but with most sergers in the $200ish price range you’d be better off just lighting your money aflame.