Searching for low hanging fruit in the maintenance schedule for my 2016 Mazda 3, the spark plugs stood out as a prime candidate. The manual recommended replacing them at 75,000 miles and I was currently sitting at around 91,000…while I had bought the car in the high 80,000s, I also thought it unlikely that they had already been replaced. My pre-purchase Carfax had revealed that the previous owner had relied on a maintenance package from the dealer and a quick scan of the stupendously cryptic notes about these conjugal visits turned up no mention of spark plugs. As for me, I’d helped (in the same way a kid “helps” bake cookies) change the plugs on Iron Van years ago, so I had a general idea of what was involved. Still, this would be my first solo attempt. My journey began the way all modern DIY quests do: with a spattering of YouTube videos and a deep dive into an eclectic mix of car enthusiast forums.

Spark Plug Basics

As spark plugs grow older, they lose their sharp edges as material from the center and ground electrodes is slowly eroded away. As the gap between these two points grows, the voltage required to bridge the gap increases proportionately. Even the best ignition systems will be strained to supply enough voltage to completely burn the fuel. It is at this point, when fuel is being left unburned, that the time has come to change spark plugs. Replacing worn out spark plugs with new ones (with sharp new edges) effectively restores the ignition system’s efficiency. Misfires are reduced, power is restored, economy of operation is enhanced, and emissions are reduced.

- NGK (https://ngksparkplugs.com/en/resources/how-often-should-i-replace-my-spark-plugs)

Changing the spark plugs is a relatively easy task, so long as you don’t:

- drop something crunchy in the spark plug holes

- mangle the screw threads on the engine block

- forget what you unplugged from where (vehicles endowed with wiccan summoning circles posing a distinct threat to insufficiently conscientious tinkerers)

Speaking of distributor caps, the Mazda didn’t even have one. It instead used something called a “coil-on-plug” (COP) ignition system. AFAICT, this transition from the distributor merry-go-round to a less roundabout coil on plug setup has been slowly genociding an entire genre of panicked forum posts.

Iron Van with his SBC 350 had not been especially picky about his plugs, which had cost me roughly $20 for all eight. The Mazda Skyactiv engines were vastly more particular, perhaps as a side effect of trying to wring high fuel efficiency out of a relatively small and high compression engine. My van’s old school V8 engine had used traditional nickel-copper spark plugs, but my Mazda needed a kind made out of Iridium. These proved quite a bit more expensive but also were supposed to last much longer. The specific fancy-schmancy NGK plugs used by Mazda were also some of the most frequently impersonated spark plugs of all time due to their relatively high cost. Tales of counterfeits infiltrating various supply chains abounded…some, like Amazon, seemingly more plausible than others. At the same time, everywhere unanimously insisted that you should only buy the OEM plugs or - failing that - the OEM’s aftermarket offering. This was because:

- “The ECU uses the spark plug as primary knock sensor. If the resistance is out of spec then you could end up losing power and or mpg.”

- “Mazda uses the plugs to measure ionization in the cylinder predicting pressure and that can predict spark knock and cylinder pressure at various crank angles.”

- “The ECU uses the ignition coils, which measure a resistance across the OEM plug for pre-ignition, and extremely low levels of knock retard the knock sensor cannot pick up, along with that it gives the ECU individual cylinder information, the spark plugs are actually used as a sensor. How it works exactly is proprietary information that I am not willing to share, you want to use OEM plugs.”

- “So are the Mazda PE5R-18-110 the same as the NGK Laser Iridium ILKAR7L11/94124 spark plug?”

- “This’s a million dollar question. Many believe Mazda OEM PE5R-18-110 and NGK 94124 / ILKAR7L11 are exactly the same plug other the Mazda logo imprint on the porcelain insulator. In fact, the OEM plug even has NGK’s “ILKAR7L11” model number on it. But OVT (OrangeVirus Tuning) had posted here insisting we have to use OEM plugs with their tuning knowledge (see post #2). And my personal opinion based on the huge list price difference between 2 plugs is they’re different. Only Mazda and NGK know the true story.”

- “Not sure what all that OVT stuff in post #2 is about the secret proprietary Mazda tuning, but said poster hasn’t been active since 2016. (Undercover Mazda parts guy??)”

- “This’s a million dollar question. Many believe Mazda OEM PE5R-18-110 and NGK 94124 / ILKAR7L11 are exactly the same plug other the Mazda logo imprint on the porcelain insulator. In fact, the OEM plug even has NGK’s “ILKAR7L11” model number on it. But OVT (OrangeVirus Tuning) had posted here insisting we have to use OEM plugs with their tuning knowledge (see post #2). And my personal opinion based on the huge list price difference between 2 plugs is they’re different. Only Mazda and NGK know the true story.”

tl;dr was that the OG Skyactiv spark plug had a very specific resistance (and/or some potentially imaginary magic sauce) used by the ECU for WhateverCalculations.

How much the Mazda PE5R-18-110 and the the NGK Laser Iridium ILKAR7L11/94124 differed was a topic of debate which I was not especially qualified to weigh in on, but the cost difference between the OEM plugs and properly-sourced aftermarket NGK offerings was only about $15/plug on a 4-cyl engine. With an expected lifespan of 100,000 miles, this amortized out to an extra $0.0006 per mile to not have to read any more headache inducing forum debates. I decided to just get the OEMs and be done with it since I would be saving several hundred dollars by installing them myself anyway. In a more financially constrained situation the runner up choice would have been the NGK ILKAR7L11s, likely sourced from Rock Auto.

Buying Parts From A “Stealership”

This was my first time ordering parts from a dealer. This may vary by brand, but for Mazda, there were a lot of independent websites selling purportedly OEM parts online. These all had rather suspiciously similar looking sites running very similar software. None of them immediately identified themselves as Mazda dealerships, but their business addresses (when I looked at Google Maps) were all shared with a Mazda dealership. Apparently most of these websites are in fact Mazda dealerships using an e-commerce package to sell parts on the Internet; you order via the website, the part is shipped to the dealer (or they have one sitting around already), and then the dealer ships it to you.

The markup on parts varied wildly from dealer to dealer, with shipping being the most unpredictable component - and the most annoying part of price discovery, since it took a lot more clicking and zip code inputting to wring a shipping estimate out of the checkout page. Weirdly, while there was a pickup option available from my local dealership, it cost the same (or evens slightly more after gas) as having them shipped to my address thanks to a “Est. Local Pickup - Handling Charge” of $14.95. (Likely the calculus changes again for larger or heavier items with weightier shipping fees, but spark plugs are relatively inexpensive to ship.) It was often cheaper still to have them shipped across the country from a more distant dealer optimizing for bulk sales over profit margins. After comparing a bunch of sites I ordered from MazdaSwag since they had the least worst prices.

General Cliff Notes

- Skyactiv OEM spark plugs have 2 types: PE5R-18-110 and PE5S-18-110

- PE5R-18-110 is made by NGK

- The NGK equivalent for PE5R-18-110 is NGK Laser Iridium spark plug ILKAR7L11 / 94124

- PE5S-18-110 is made by Denso

- The Denso equivalent for PE5S-18-110 is Denso ZC20HPR11

- One should use either the OEM plugs or the closest NGK/Denso equivalent (absolutely no random discount bin plugs)

For reasons I don’t understand, no one really talks about the Densos, only about the NGKs- “You can’t get OEM Denso plugs PE5S-18-110 from any Mazda dealers in the US as far as I know.”

- PE5R-18-110 is made by NGK

- The torque spec is 15—20 N·m / 1.6—2.0 kgf·m / 12—14 ft·lb

- One should NOT add grease to the spark plug threads because this wildly distorts the required torque specs

- Per NGK: “Anti-seize can act as a lubricant, altering torque values up to 20 percent, increasing the risk of spark plug thread breakage and/or metal shell stretch. Thread breakage can sometimes involve removing the cylinder head for repair. Metal shell stretch changes the heat rating of the spark plug and can result in serious engine damage caused by pre-ignition. Do not use anti-seize or lubricant on NGK spark plugs. It is completely unnecessary and can be detrimental.”

- One should NOT add grease to the spark plug threads because this wildly distorts the required torque specs

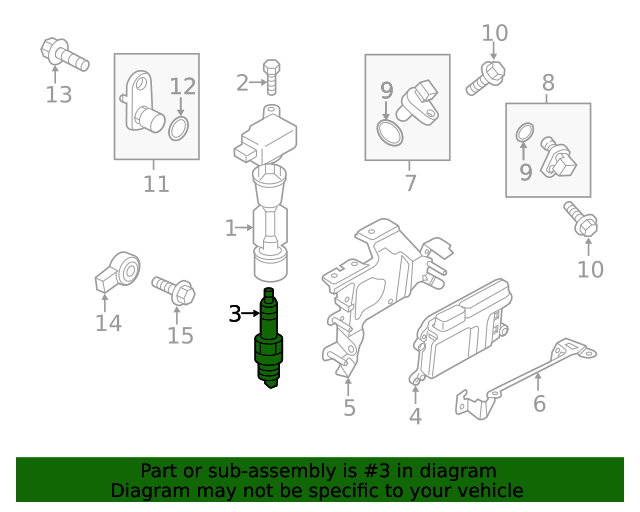

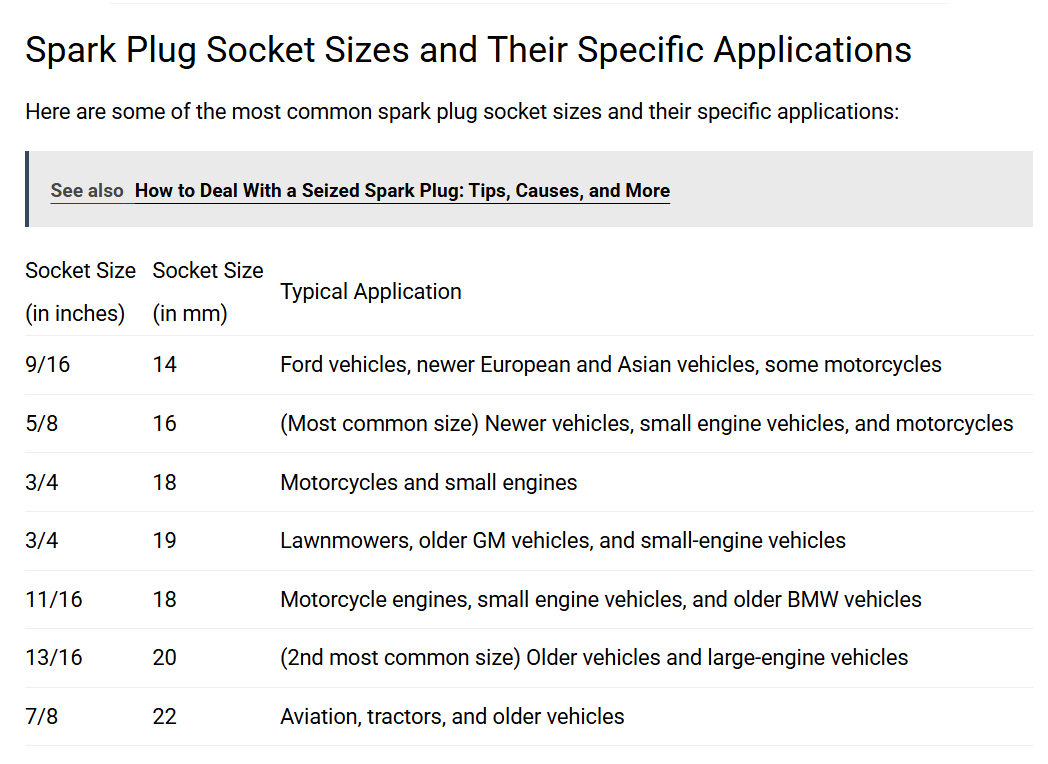

- Mazdas typically require a 9/16 or 14mm spark plug socket (most cars are 5/8”)

- “All spark plugs are 6 sided, except some BMW engines” (lol)

- The PE5R-18-110/OEM equivalent plugs should be good for up to 100,000 miles

- On top of electrode wear, leaving the plugs in much longer than this can cause them to be extremely difficult to remove

- Most modern cars have aluminum cylinder heads which are relatively soft so it’s easy to mangle the threads.

- If you mangle the threads, you are in trouble since they are part of the engine block.

- The spark plugs should always be hand-threaded to prevent cross threading.

- Plugs should be replaced on a cold motor to avoid thread damage.

- If you are having trouble getting them out, then a warm engine might help.

- A lot of convo about “gapping” spark plugs (adjusting the spacing between the source and the sink) but apparently that’s not relevant in $CURRENT_YEAR and/or for my kind of car

- But try not to drop the spark plugs on their heads because if they get brain damage that might mess up the gap

- It’s good to label the spark plugs as they come out so you can inspect their condition and known what cylinder they came from should you find anything sus

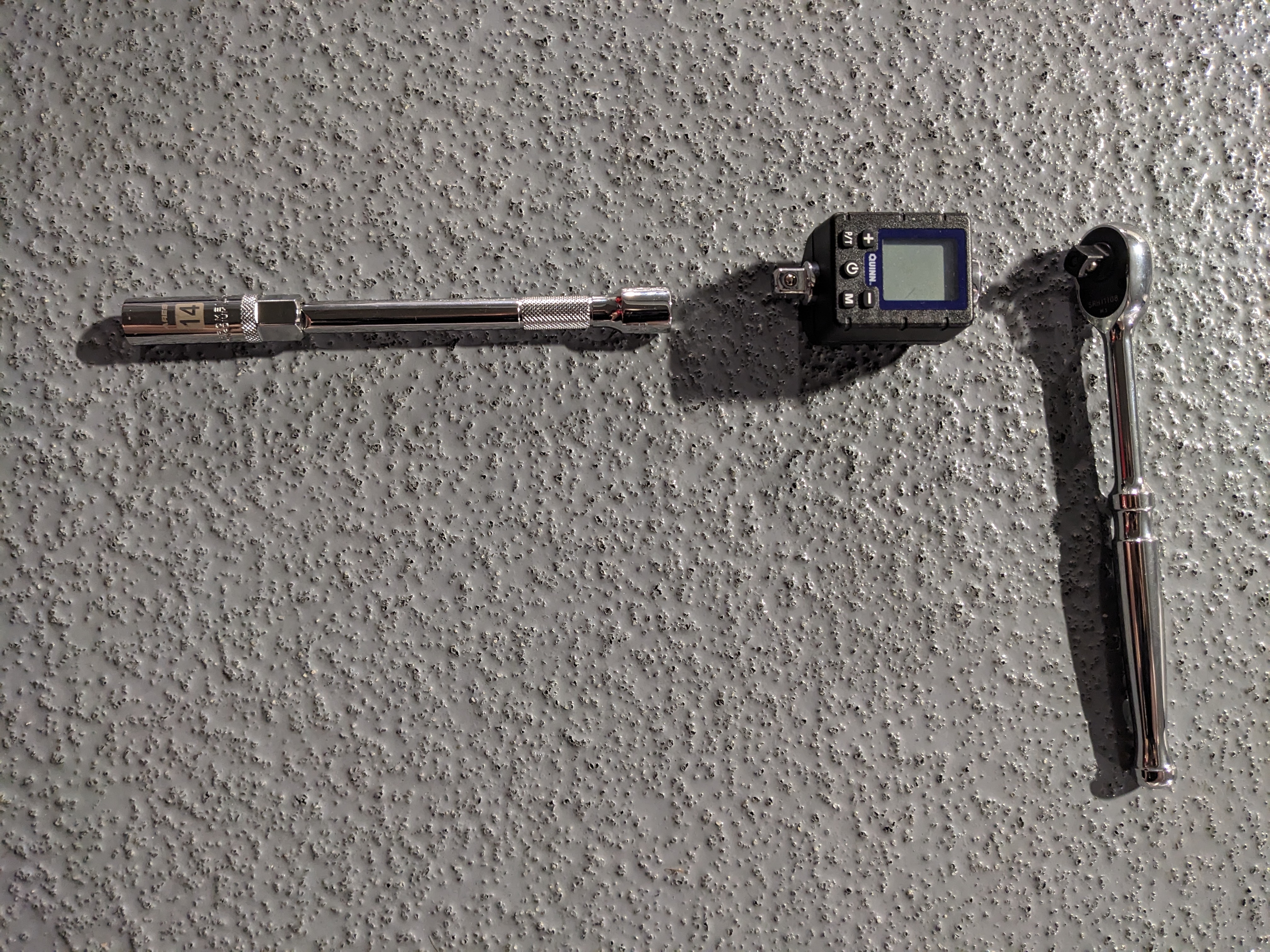

I also wanted to make sure I had a way to confirm I wasn’t overtightening or undertightening the plugs, so I researched torque wrenches. You can do it by feel if you’ve got experience but…the whole point of doing this was so that I could develop said experience. I opted to get a digital torque adapter rather than a dedicated torque wrench, since I liked the modularity of the separate unit and the impression I got from my reading was that torque wrenches were generally 1) expensive 2) easily broken and/or de-calibrated.

Dedicated spark plug sockets are long and extra skinny to fit down the spark plug hole and often have something (either rubber in the socket or a magnet) to help grip the spark plug while inserting it so it doesn’t fall in/off. People seemed to generally find the magnet kind to be less annoying than the rubber kind.

To summarize, I assembled the following materials:

- PE5R-18-110A Ngk Plug Spark ($25.81 x4 = $103.24, shipping was $12 (but I’d gotten some other stuff too))

- Harbor Freight QUINN 3/8 in. Drive 5.9-59 ft. lb. Digital Torque Adapter ($40)

- ARES 11017 14mm 12-Point 3/8-inch Drive Thin Wall Magnetic Spark Plug Socket ($13 because I was lazy and paid too much on Amazon)

- ratchet + 6” extension bar

- 8mm socket (to remove the coil packs)

- silicone paste (to gently slime the rubber boots of the coil packs for future smooth re-removal)

- work lights

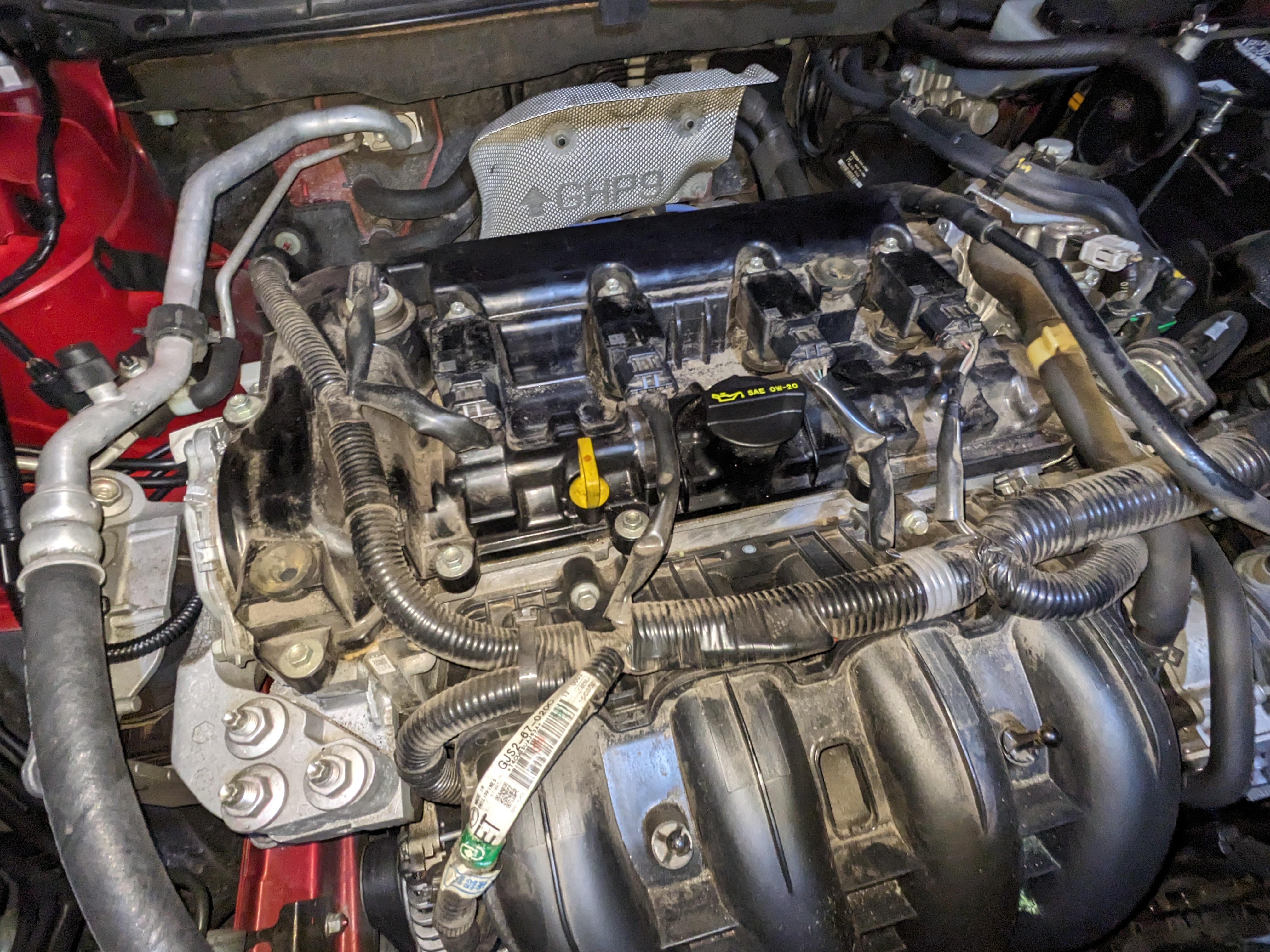

My Mazda has a SkyActiv-G 2.5L engine, which is used across quite a few vehicles in Mazda’s lineup. I found the photos on this blog to be very helpful, even though it’s technically for a CX-5.

When my bag of spark plugs arrived, I noticed one teeny-tiny issue: there were only 3 spark plugs in the bag. (#CompetencyCrisis) After confirming that my order receipt showed I had paid for four, I sent a short complaint email about my Mazda not being a 3 cylinder car and the 4th was sent on its way…via painfully slow shipping. :I <insert time skip here>

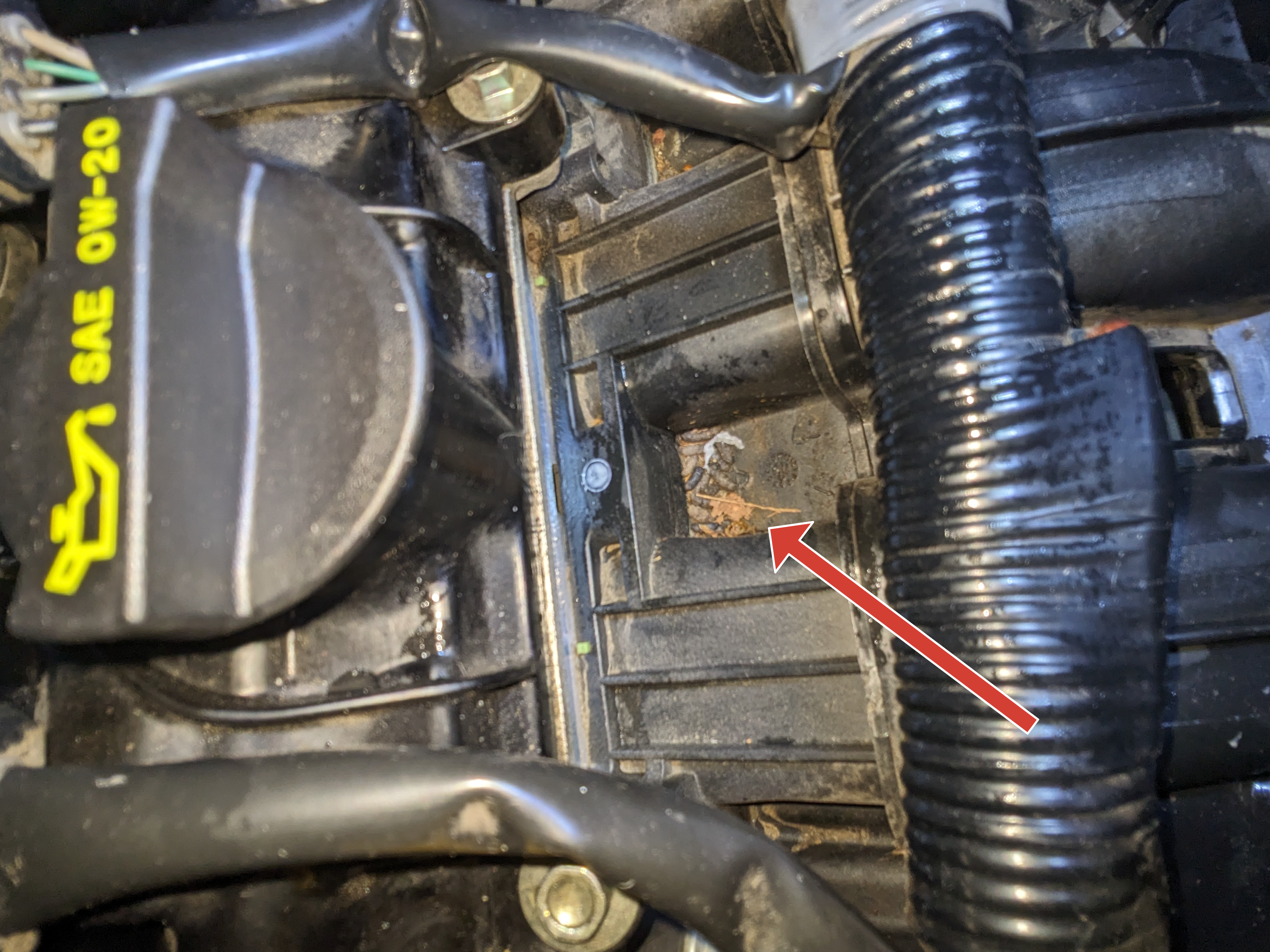

In the meanwhile, I had a look at my engine bay, which was quite dirty. The black plastic engine cover just pulls right off easy peasy. I found a variety of questionable turd shaped objects underneath.

I checked to see if something was supposed to go on the top of the engine bay hood to deaden the sound, since it looked like something ought to go there, but apparently not. I watched some videos on how to safely hose down an engine bay, but decided not to get too crazy with it and just did a solid spray-bottle + wipedown of everything I could instead, with the exception of the hood (I carefully hosed that area a little bit since I found it hard to clean).

I had a small Harbor Freight handheld work light and some flashlights, but thought something a little brighter would be helpful, so I got this NEBO OMNI 2K Work Light. Everything about this light was just barely enough. The magnet barely held on, and it just barely gave enough light for me to see tf I was doing. I still plan to look for an upgrade later, but the way the light folds in the middle makes it very useful.

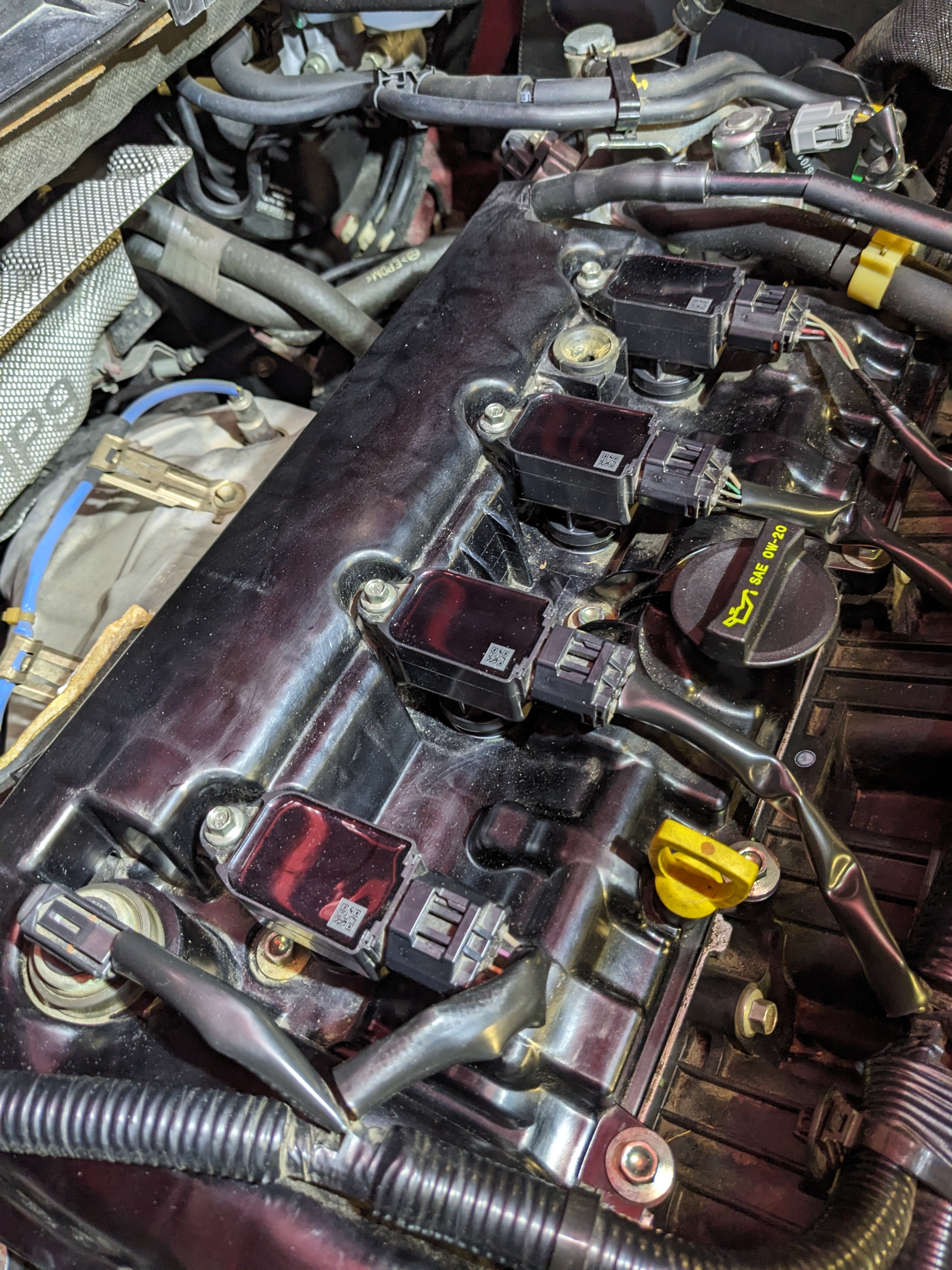

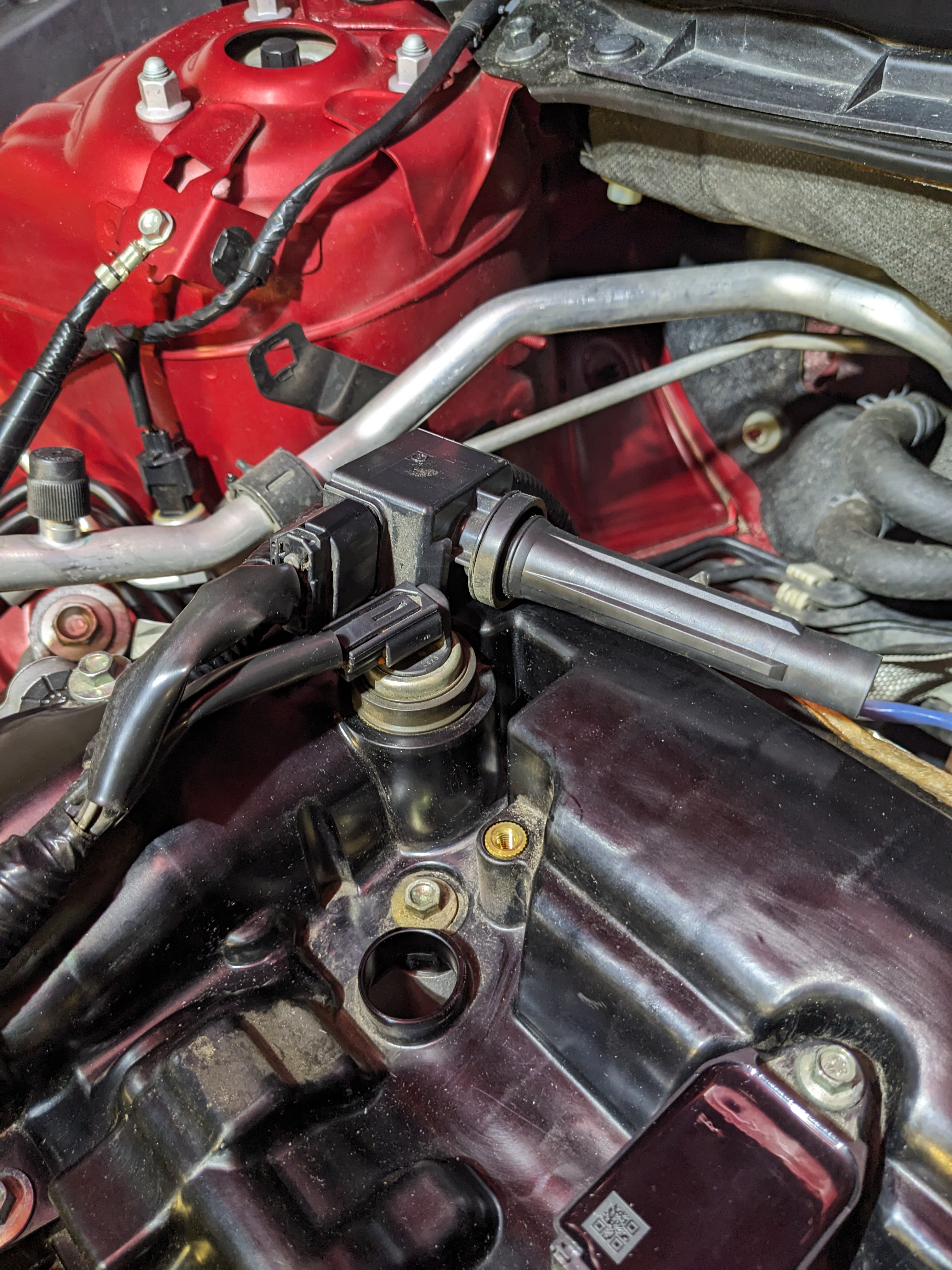

Now that the fourth spark plug had arrived, the first step was to remove the coil packs, which sit on top of each of the four spark plugs. I unclipped the black clips and unscrewed the 8mm bolts, then vibro-wiggled them free. They had slightly fused into place, but the wiggling movement combined with turning them back and forth helped get them unseated. I put a SMALL amount of dielectric grease on the inside of the ignition coil rubber that touches the porcelain on the spark plug. (The whole point of a spark plug is to zap things so you don’t want to put anti-zapping grease in the wrong spot.)

I hadn’t been able to clean underneath the coil packs before so I did that as I went. The coil packs need to go back to the exact same spot, but (unlike on the small block chevy) it’s obvious which one goes to which on the Mazda due to the layout of the inline four wiring harness.

Peeping on the spark plug in its socket before removing it from its hole.

Old plugs all removed.

Old vs new. I snapped the pic and sent it off to a more car-literate friend to read the tea leaves and his first reply was the OG image of a certain Chainsaw Man panel, lol. Apparently it might also be time to replace my PCV valve gasket - the oil on the threads indicates that the seal has aged/degraded to the point that it’s starting to let small amounts of oil seep down into the holes to slime up the plugs.

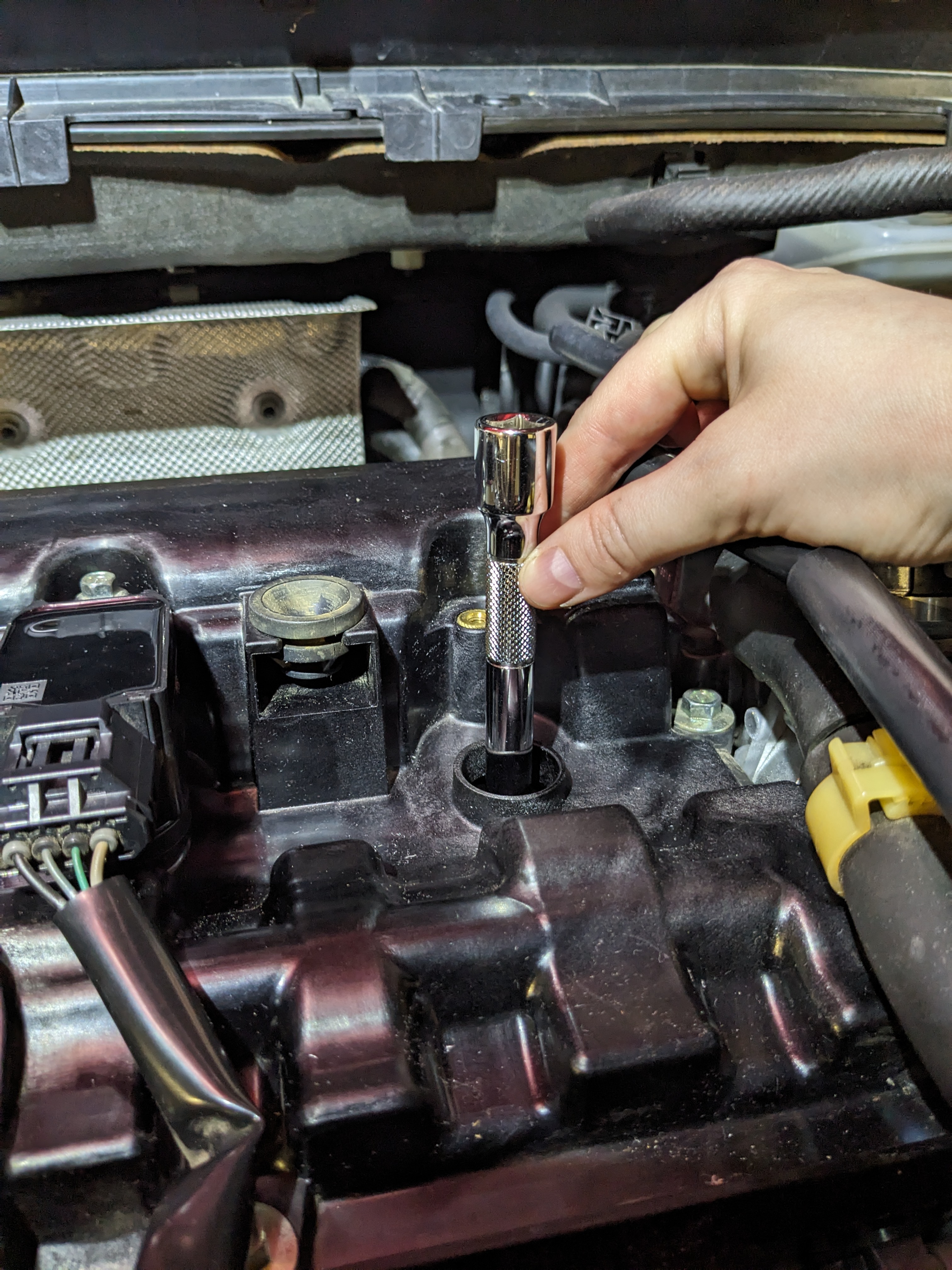

I loaded a new spark plug into the magnetic spark plug socket and began hand screwing it in, only adding the ratchet at the end. Once the plug was snugged, you had to get the coil boots back on, which was easily the hardest part of the whole thing. Feeling whether they’ve engaged or not is a bit muddy. The tiny bit of lube on the inside helped a lot, though.

On the third socket, it seemed like I was needing to use a lot more force than I should…the torque meter reading seemed to be reading far too low for the amount of pressure I was applying…maybe it wasn’t fully seated? Just as I decided to pull the whole thing out and see what was going on, I heard a high pitched pinging noise, like a tea spoon rapping a hollow tea cup. Convinced I had destroyed my cylinder head threads, I pulled the spark plug out and inspected it…but I didn’t see anything…still, something had made that unnerving noise. I slept on it and pulled it again in better light.

Uh-oh. Good thing I re-checked. That unidentifiable noise had been the ceramic insulator cracking. I think what probably happened was that the socket was ever so slightly askew and not completely seated which in turn threw the torque metering off. This might be one downside of using a torque adapter instead of a dedicated torque wrench: the extra joint gives it just enough extra play to be dangerous. In any case, I had not seen this possibility (or noise) mentioned in any of the resources I read, so I thought I’d add my first timer’s perspective to the internet at large for discoverability in case it happens to anyone else. Talking with a shadetree mechanic friend, the quality of plugs has also gone down a lot in recent years, to the point where 1 out of every 50 or so plugs he installs breaks in some way (imagine the amount of spark plug changes you have to be doing per year to come up with such a stat…). However, I’d gone with the fancy OEM plugs specifically to head off such QC hazards, so the most likely cause of the porcelain cracking was simple user error.

In any case, I put the old spark plug in and (AGAIN) waited for the new spark plug to arrive. At least this time I only had myself to blame. :P

After it arrived, I put it in and took the car for a test drive. Maybe it idled a little smoother, or maybe that was my imagination…in any case, despite the small outbreaks of Murphy’s law, it was a good learning experience. I was glad to have done it myself, saved some money, and most importantly, had an excuse to buy a few more tools. ;)

Resources

- https://ngksparkplugs.com/en/resources/5-things-you-should-know-about-spark-plugs

- https://ngksparkplugs.com/en/resources/read-spark-plug

- https://www.reddit.com/r/mazda/comments/1afkw47/anyone_know_what_the_a_in_pe5r18110a_spark_plug/

- https://paulstravelpictures.com/Mazda-CX-5-Skyactiv-G-Engine-Spark-Plugs-Replacement-Guide/index.html

- https://www.youtube.com/watch?v=UPrRHkKEGfE (video overview)

- https://mazdas247.com/forum/t/skyactiv-spark-plug-question.123872850/

- https://mazdas247.com/forum/t/ngk-spark-plug-ilkar7l11-long-term-usage.123878882/page-2